De lijn met eenvoudige en redelijke structuur, hoge precisie, gemakkelijke bediening en menselijk ontwerp voldoet meer aan de moderne samenstelling. Op grote schaal gebruikt in de farmaceutische, dagelijkse chemische, voedingsmiddelen- en speciale industrie. Het is het ideale apparaat voor de kwantitatieve vulling met hoog viskeuze vloeistof en zalf. De lineaire lijn kan worden gekoppeld aan de cap-feeder en de capping-machine die de capping-lijn vult. Met de functie van gemakkelijke aanpassing en eenvoudige reiniging.

Productomschrijving:

1. Adopting piston filling, with high filling precision & easy to disassemble & maintain. There are gravity-type filling, overflowing-filling, weighing-type filling & pump type filling as option for different packages & materials.

2. With humanized design & linear bottle-enter-exit, easy & quick to adjust whole system to meet different bottles production.

3. Filling volume can be adjusted directly via touch screen;

4. Filling speed is easy to control, no bottle no filling. With auto liquid supply system to meet continuous filling & anti-drip filling nozzles to ensure no dripping.

5. Filling is designed with one-button washing function, & can meet CIP online washing if required.

6. Multifunctional capping system is suitable for various threaded caps, like flip caps, spray pump caps, & 3/4-circle caps etc, easy to adjust to meet different bottles, capping force is adjustable, no damage to bottles & caps.

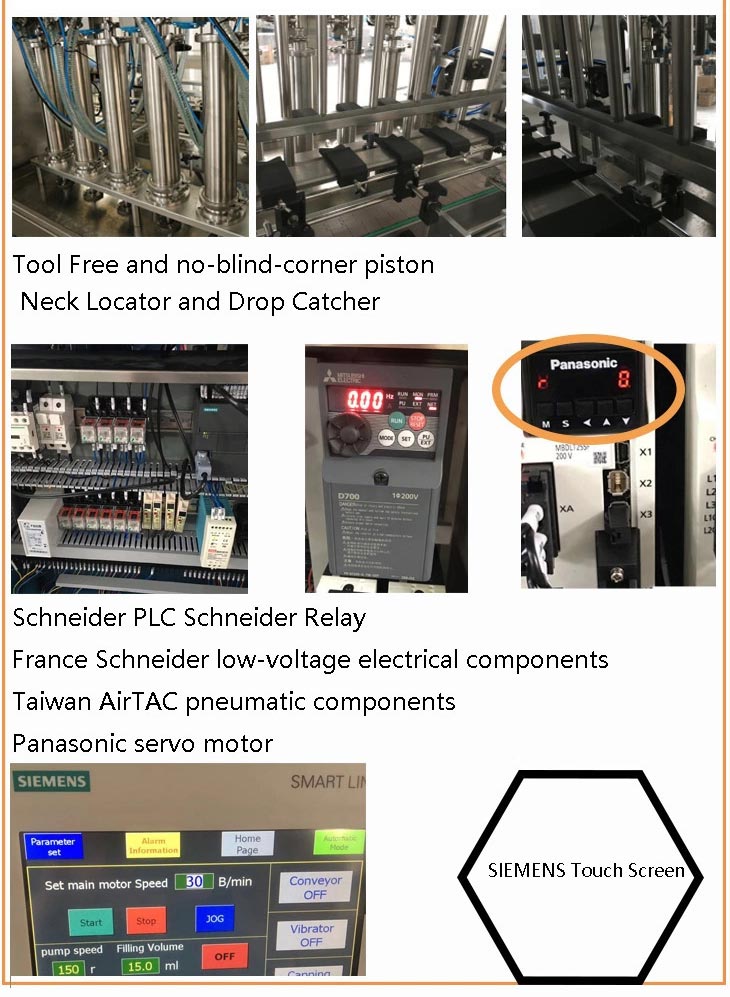

7. With PLC, touch screen to operate, auto counting & with formula saving.

8. All moving parts or electrical, or pneumatic parts are world-famous brands, which ensures the stable & durable running.

9. Mainly made from top-quality stainless steel, all steel parts contacting liquid are stainless steel 316, delicate & durable.

10. Can be customized to the anti-corrosion filling capping line.

11. Kan strikt op basis van CE-normen worden ontworpen en gemaakt.

Main Technical Parameters:

| Filling scope | 100-1000 ml | 300-3000 ml | 500-5000ml |

| Vulmondstuk | 8-nozzle | ||

| Capperchoose | Multifunctional capper/ High speed capper | ||

| Diameter kap | 22-55mm | ||

| Capaciteit | 30-60bpm | ||

| Vulfout | ±0.5%(maximum filling volume) | ||

| macht | 220V/380V 50/60HZ2.2KW | ||

| Suitable Bottle | 50-330mm | ||

| Dimension(H x L x H) | 5900x800x1900mm | ||

| Bruto gewicht | 420kg | ||

Verpakking en verzending

Packaging:

Alle machines worden bewaard in standaard export houten kist (halfautomatische vulmachine)

Shipping:

1) Small machines will be shipped by express (DHL, EMS, FedEx ,TNTand so on) or By Air Port.

2) Zware machines worden over zee vervoerd.

3) Leading time: 1-3 working days ( semiautomatic filling machine )

Payment:

LC, T / T, Western Union, Money Gram zijn beschikbaar

Onze diensten

1) Prompt reply: We will answer your enquiry within 12 hours

2) Warranty time: 1 jaar

3) Installation and use guide: We can offer theinstruction manual and video of the machine for you

4) After-sales service: We will follow up our customers all the time after selling out the machine. Please let us know if you meet any question about the machine.

5) Accessories: We supplythespareparts with competitive price if you need.

6) Factory and selling team: We have factory in Guangdong and we have experienced selling team which can communicate in English well. Welcome to visit us at any time.